In today’s world, where freshwater scarcity is becoming a pressing challenge, Zero Liquid Discharge (ZLD) and advanced water recovery have emerged as indispensable strategies for sustainable industrial growth. At UY Trienviro, we believe water is a precious resource — and our cutting-edge ZLD systems and water recovery solutions are designed to make industries water-neutral while minimizing environmental impact.

Why ZLD & Water Recovery Matter

Industrial processes, especially in sectors such as tannery, textile, distillery, dairy, and sugar manufacturing, generate significant volumes of wastewater containing dissolved salts, organic compounds, and other pollutants. Conventional treatment methods often fall short in reclaiming this water, leading to environmental discharge and resource wastage.

Technical Strengths of UY Trienviro’s ZLD Solutions

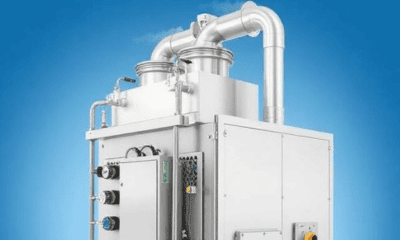

Our ZLD systems are engineered for high-performance across industries such as tannery, textile, sugar, dairy, distillery, and chemical processing. Key features include:

Our ZLD & Water Recovery Impact

Industries partnering with UY Trienviro have witnessed remarkable benefits:

• Reduction of freshwater consumption by up to 90%.

• Minimization of liquid waste discharge, ensuring full regulatory compliance.

• Significant savings in operational costs over the plant’s lifecycle.

• Contribution toward corporate sustainability goals and environmental stewardship.

A Vision for Water Sustainability

At UY Trienviro, we are driven by the vision of a future where no drop is wasted. Our ZLD and water recovery systems are more than just technology — they are a promise to industries and the planet alike.

We transform industrial wastewater into a resource, enabling companies to thrive sustainably while meeting regulatory and environmental commitments. Together, we can achieve a water-neutral future.