-

TUBE SETTLER

Tube Settlers are used in solid and liquid separation. It separates solid sludge from wastewater. This process is purely based on gravitational. Media used in tube settlers increases the settling capacity. Multiple tubular channels are sloped at an angle of 60° and are adjacent to each other, which combine to form an increased effective settling area. UY Trienviro provides customized tube settlers as per the client’s specifications.

-

MULTI-GRADE SAND FILTER

In Multi Grade Sand Filter or Pressure Sand Filter, water is passed through multiple layers of filter media consisting of graded sand, pebbles, and gravel layers. The contaminants in the water are captured in the media bed and filtered water passes into the discharge manifold at the bottom of the tanks. UY Trienviro provides manufactures with MSEP, SS, and FRP tanks using high-grade filter media, pressure gauges, and valves.

-

ACTIVATED CARBON FILTER

An Activated Carbon Filter (ACF) works on the principle of adsorption. The filter media adsorbs or reacts with pollutant molecules, and then filtered water is drained out. Activated carbon which is used as a medium to remove contaminants is a natural material derived from coconut shells, lignite, bituminous coal, etc. Activated Carbon Filters are installed after MGSF to remove color, odour, free chlorine, and oil & grease. UYTrienviro provides manufacturers ACF in MSEP, SS, and FRP tanks using high-grade carbon (600 – 1000 IV), pressure gauges, and valves. We also cater to special requirements. Note: Dual Media Filter is also available.

-

SOFTENER

Softener is used to remove the hardness of wastewater using the Ion Exchange process. The hard water flows through the bed of cation resin which causes the calcium and magnesium ions in the hard water to be exchanged for sodium ions. UY Trienviro manufactures softeners in MSEP, SS, and FRP tanks using high-grade resin pressure gauges and valves. We also provide customized solutions.

-

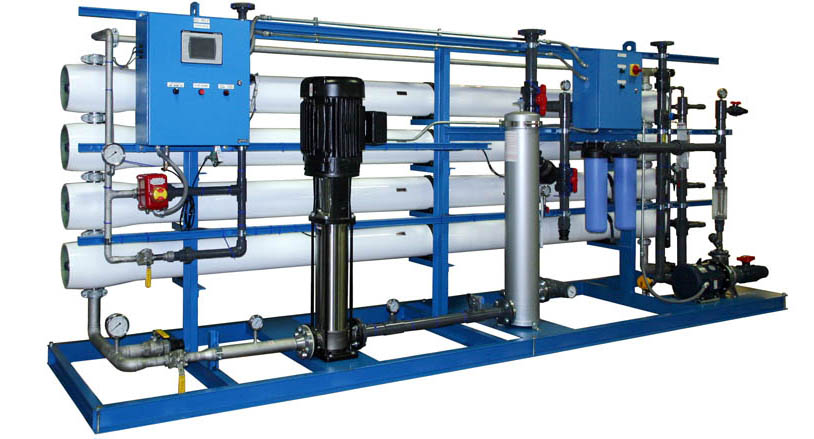

INDUSTRIAL RO PLANTS

Reverse Osmosis is a completely self-contained unit provided with all internal and external water connections by means of plastic pipe/tubing for feed water to be connected to the source of water, product water and reject water which is suitable for high-pressure operation and for drinking water use. It can be integrated with the existing filtration system to meet region-specific water quality standards. UY Trienviro provides customized solutions as per requirements.

-

MEMBRANE BIO REACTOR

The Membrane Bio-Reactor (MBR) is the technology of membrane separation combining with traditional sewage biology treatment tech. It reinforces the biological treatment of sewage treatment and recycling technology, it is also called membrane separation activated sludge treatment. MBR holds the activated sludge and big molecule organics in the aeration tank increases the sludge concentration. In the meanwhile, the pollutants can be degraded in the tank further and effectively, making the permeate water quality cleaner. Due to the precision of membrane filtration, the permeate water is clean and clear, so it can save the secondary sedimentation tank to increase the efficiency of solid-liquid separation.

-

PACKAGED SEWAGE/ EFFLUENT TREATMENT PLANT

UY Trienviro designs, fabricate, install, and commissions different capacities of packaged sewage/effluent treatment plants as per the customer’s requirements. These are suitable for rural areas, highway rest stops, hotels, restaurants, and hospitals mainly where the population is small or space is less or the required plant capacity is small. The treatment scheme starts from bar screen, oil & grease trap, that flows to equalization tank which allows the flows coming to the plant to be held and pumped at a uniform rate to the plant. There are also alternate designs with MBR & MBBR technology for a reduced footprint. The treated discharge is then disinfected with hypochlorite or ultraviolet or ozonation system depending upon the client’s requirements. Final discharge is normal to a stream with sufficient dilution to safely assimilate the remaining 5% of the pollutants without measurable harm to the environment.

-

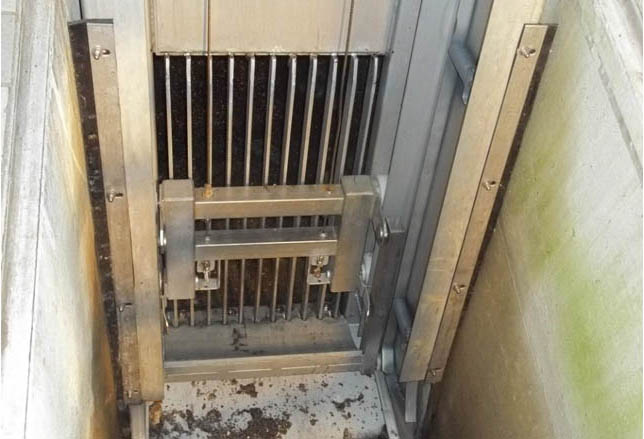

BAR SCREEN

Bar screens are used in the primary treatment of effluent/sewage to segregate larger impurities from the wastewater. The main purpose is to remove larger debris from the effluent so that it doesn’t harm the electro-mechanical equipment in the plant. We can provide it in MOC such as MS, SS, FRP, MSEP depending upon the effluent and requirement. The porosity ranges from 2 mm to 20 mm.

-

UYT AERATOR

UY Trienviro is offering revolutionary technology for aeration. UYT Aerator is the second-generation-aeration system, which maintains traditional aerator advantage and improves the installation and O&M experience of the wastewater treatment plant. UY Trienviro Aerators have a specially designed bubble-cutting mode. The bubble is smaller and the oxygen utilization rate is higher. DO value in the pool is maintained. The airflow is ejected from the nozzle at high speed, forming a strong negative pressure at the bottom of the aerator, and the sewage and activated sludge at the bottom of the aerator are sucked into the aerator to achieve the first efficient cutting. The mixture flows through the spiral guide plate, and under the action of the rotary cutter, generates the violent vortex flow. This is the second efficient cutting. Then, the spiral airflow cuts through the specially designed multi-layer cutting piece, after eight times multiple cutting, a large number of fine air bubbles and some micro and nano air bubbles are produced, achieving the third efficient cutting. The spiral flow jets from the UY Trienviro aerator with high speed, diffusing around under the action of centrifugal force, forming many small whirlpools in the flow field, achieving the fourth efficient cutting. The aerator resistance loss is almost zero, reducing blower failure and reducing comprehensive energy consumption by 10-30%. Large upwelling cyclone, strong stirring force, zero oxygen-filled blind areas, zero silt deposit at the bottom of the pool is suitable for all kinds of high concentration wastewater. It is non-plugging, anti-corrosive, anti-aging. It is suitable for very corrosive effluent, has high hardness, and has high scaling. It is also suitable for other difficult sewage treatments. It has high strength, high toughness. It has no movable and fragile parts which make it stable, strong, and durable with a service life of 10-20 years. It covers a larger service area, lowers pipeline costs, increases cost-effectiveness, and is required in lesser numbers.