Transforming Water Management for a Tannery

Tackling High TDS & Reducing ZLD Costs with Smart Water Solutions

Water has always been central to the leather tanning industry. However, with increasing environmental regulations and the push for Zero Liquid Discharge (ZLD), many tanneries are grappling with rising operational costs, high Total Dissolved Solids (TDS), and the challenge of sustainable water management.

Calico Impex, a leading tannery, faced this very challenge. Their existing setup was unable to efficiently manage high TDS wastewater while keeping costs under control. With the dual objectives of regulatory compliance and operational efficiency, they partnered with UY Trienviro to find a sustainable, long-term solution.

That’s where UY Trienviro stepped in — with an advanced and customized approach to wastewater treatment.

The Challenge

- High Total Dissolved Solids (TDS): Conventional wastewater treatment methods struggled to handle the elevated TDS levels in tannery effluent.

- Zero Liquid Discharge (ZLD) Compliance: Strict regulatory requirements demanded complete water recovery and safe handling of waste.

- Escalating Operational Costs: High energy consumption in evaporation units and sludge handling was driving costs upward, affecting profitability.

The Solution

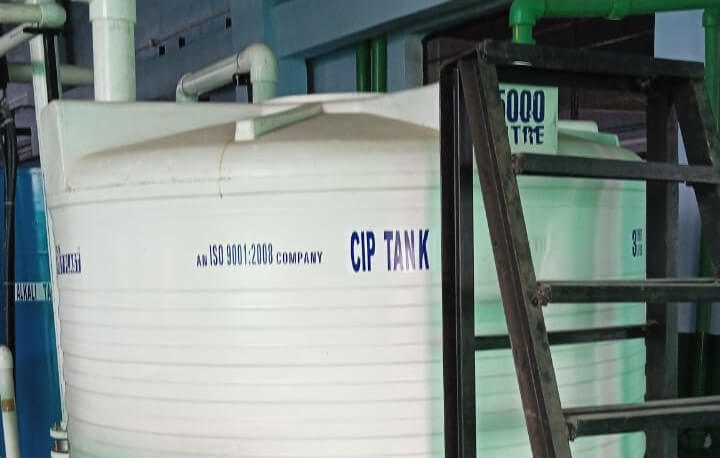

UY Trienviro, in collaboration with its esteemed membrane technology partner Hydranautics – A Nitto Group Company (Japan), designed a customized High-Performance Reverse Osmosis (HPRO) system tailored to the tannery’s unique needs. The system was integrated with:

- Brine recycling technology, reducing freshwater demand.

- Minimal evaporation requirements, cutting down energy use.

- Deployed specialized membranes designed to handle high TDS with greater efficiency and longer life cycles

The Results

- 40% reduction in operating costs compared to conventional ZLD setups.

- Substantial reduction in evaporation load, lowering energy consumption.

- Lower sludge disposal, reducing environmental burden.

- Sustainable water reuse, aligning with global best practices.

Technical Collaboration

This achievement was made possible through the wholehearted support of Hydranautics’ technical team. R&D Experts from Japan visited the site, evaluated system performance, and validated the breakthrough results achieved at Calico Impex.

Their expertise and advanced membrane technology played a pivotal role in ensuring that the solution was not only technically sound but also scalable for long-term operations.

Calico Impex

Highlights

- We installed he 1st of its kind RO Plant in the country.

- Recovery of permeate is more than 90%

- First of its kind, Brine Recovery System reduces the CAPEX & OPEX of the expensive MEE.

- PLC automated plant for superior efficiency

- Location: Banther, U.P.

- Products: RO

- Industry: Leather

- Sector: Private

A Step Towards a Greener Leather Industry

This case sets an important precedent for the leather sector, showcasing how technology, collaboration, and innovation can reduce the environmental footprint of one of the most challenging industries.

At UY Trienviro, our mission is clear — to provide smart water solutions that balance industrial growth with environmental responsibility.

With partners like Hydranautics, we are redefining wastewater management for industries that aspire to a greener, more sustainable future.

Encouraged by the remarkable success at Calico Impex, Everest Exports, one of the leading tanneries in Kanpur, Uttar Pradesh, has also entrusted UY Trienviro with implementing this innovative solution in a complete ETP-ZLD project. The project is already under the final stage of its execution, reaffirming industry confidence in our team’s expertise and sustainable approach, further reinforcing our role as a trusted partner in sustainable leather processing.